Lift Check Valves: Structure, Dynamics, Applications

The lift check valve stands as a cornerstone component within fluid control systems, providing a robust solution for thwarting backflow. In this comprehensive exploration, we delve into the structural intricacies, operational dynamics, and wide-ranging applications of lift check valves, illuminating their pivotal role across diverse industrial domains.

1. Structural Features

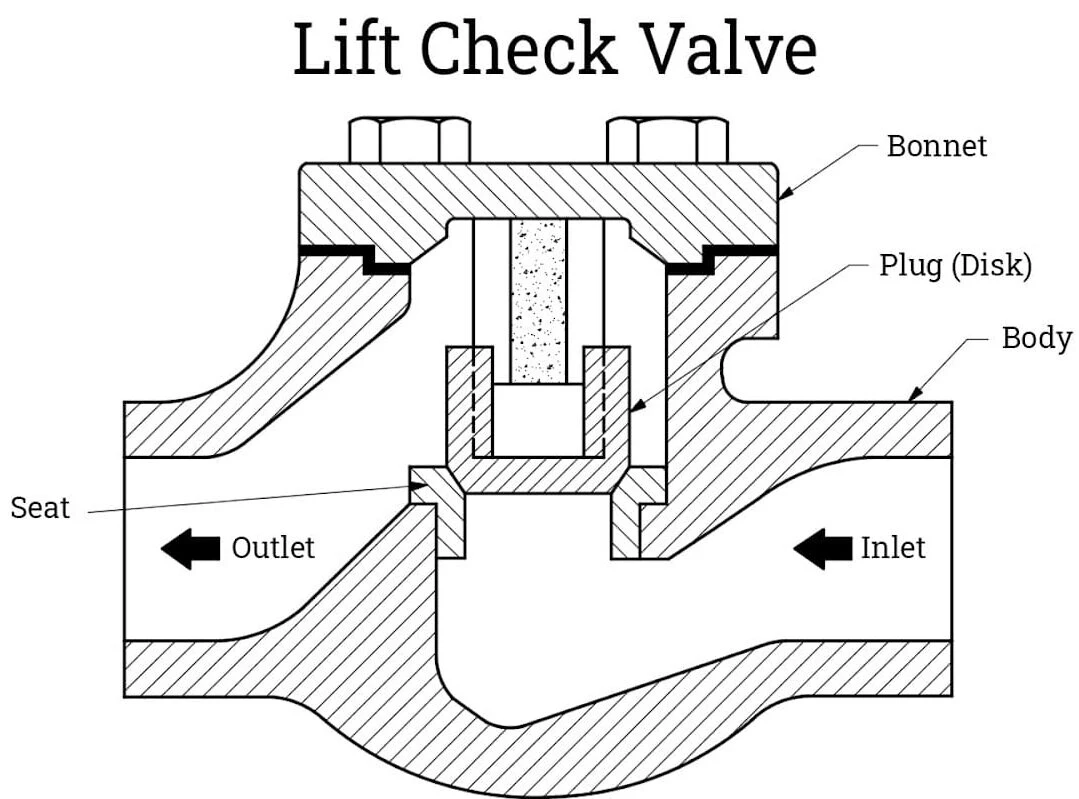

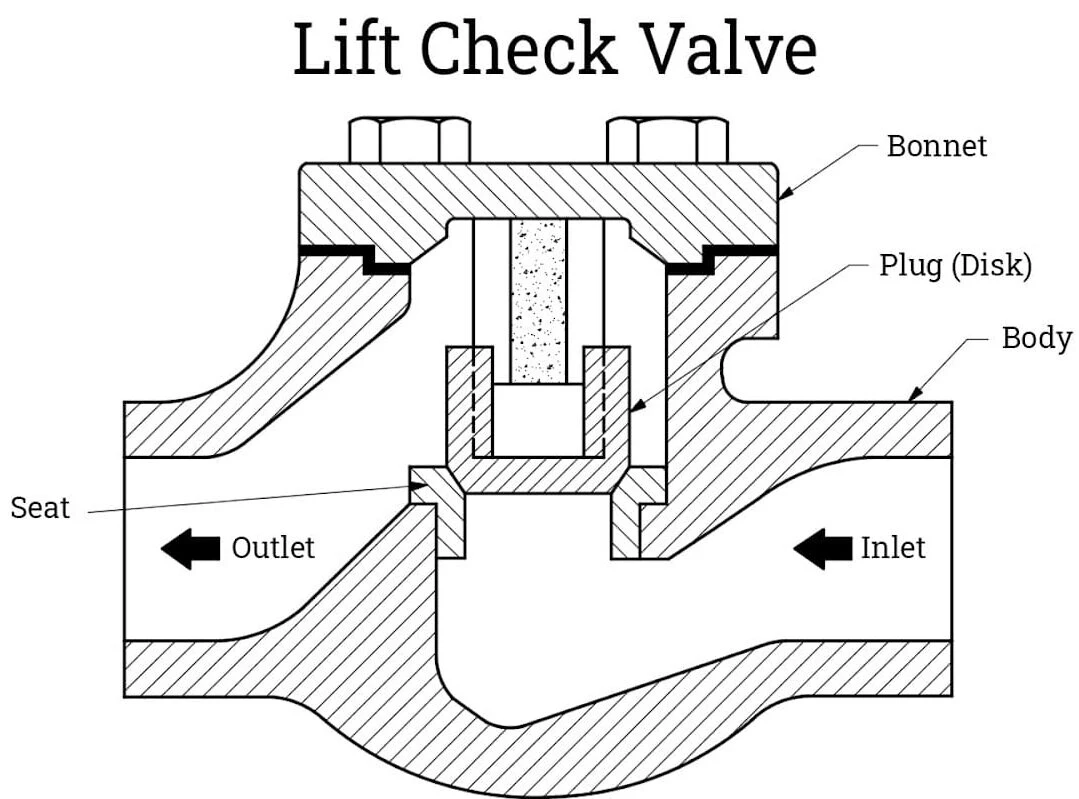

Lift check valves boast a design characterized by simplicity yet effectiveness, comprising key components including the valve body, valve disc, and guiding mechanism. Structural variations encompass configurations accommodating straight-through flow, vertical orientation, and angular flow paths. Moreover, these valves offer multiple connection options such as threaded, flanged, clamp-connected, or welded, catering adeptly to a myriad of installation exigencies.

2. Operational Dynamics

The operational paradigm of lift check valves is elegantly straightforward yet inherently dependable.

This intrinsic design attribute confers upon lift check valves commendable sealing efficacy and operational steadfastness, ensuring sustained functionality across diverse operational scenarios.

3. Versatile Applications

Lift check valves find extensive utility across a spectrum of industrial domains:

In summation, lift check valves stand as indispensable linchpins within fluid control systems, celebrated for their simplicity, reliability, and adaptability. Their adeptness in curtailing backflow across diverse applications renders them indispensable for safeguarding operational efficiency and system robustness. When deliberating upon lift check valve selection, meticulous attention to factors including operational conditions, fluid characteristics, and system requisites is imperative to ensure optimal performance and enduring reliability.

1. Structural Features

Lift check valves boast a design characterized by simplicity yet effectiveness, comprising key components including the valve body, valve disc, and guiding mechanism. Structural variations encompass configurations accommodating straight-through flow, vertical orientation, and angular flow paths. Moreover, these valves offer multiple connection options such as threaded, flanged, clamp-connected, or welded, catering adeptly to a myriad of installation exigencies.

2. Operational Dynamics

The operational paradigm of lift check valves is elegantly straightforward yet inherently dependable.

Forward Flow:

As fluid progresses in the forward trajectory, the resultant pressure propels the valve disc away from the valve seat, thereby unsealing the valve and facilitating fluid passage.

Reverse Flow:

Conversely, in the event of fluid backflow, the valve disc, influenced by its weight, spring force (if present), and the counteractive pressure of the backflowing fluid, promptly resettles onto the valve seat, effecting valve closure and thwarting reverse flow.

As fluid progresses in the forward trajectory, the resultant pressure propels the valve disc away from the valve seat, thereby unsealing the valve and facilitating fluid passage.

Reverse Flow:

Conversely, in the event of fluid backflow, the valve disc, influenced by its weight, spring force (if present), and the counteractive pressure of the backflowing fluid, promptly resettles onto the valve seat, effecting valve closure and thwarting reverse flow.

This intrinsic design attribute confers upon lift check valves commendable sealing efficacy and operational steadfastness, ensuring sustained functionality across diverse operational scenarios.

3. Versatile Applications

Lift check valves find extensive utility across a spectrum of industrial domains:

Water Systems: Integral to water supply and drainage pipelines, these valves facilitate efficient flow control while mitigating the deleterious effects of water hammer.

Steam Systems: Playing a pivotal role within steam trap valves, lift check valves prevent condensate backflow, thereby preserving system efficiency and integrity.

Specialized Environments: In locales characterized by elevated water hammer pressures or frequent alterations in fluid flow direction, such as certain pipeline configurations, lift check valves emerge as stalwart guardians, delivering unwavering performance and stability.

Steam Systems: Playing a pivotal role within steam trap valves, lift check valves prevent condensate backflow, thereby preserving system efficiency and integrity.

Specialized Environments: In locales characterized by elevated water hammer pressures or frequent alterations in fluid flow direction, such as certain pipeline configurations, lift check valves emerge as stalwart guardians, delivering unwavering performance and stability.

In summation, lift check valves stand as indispensable linchpins within fluid control systems, celebrated for their simplicity, reliability, and adaptability. Their adeptness in curtailing backflow across diverse applications renders them indispensable for safeguarding operational efficiency and system robustness. When deliberating upon lift check valve selection, meticulous attention to factors including operational conditions, fluid characteristics, and system requisites is imperative to ensure optimal performance and enduring reliability.