Titanium Swing Check Valve, TA2, BS 1868, 2-1/2 Inch, 150 LB

Key Specifications / Features

Model no.: JSC-240123-SCV-02

Hits: 17

Our Titanium Swing Check Valve, manufactured in China, adheres to BS 1868 standards, ensuring top-notch performance and reliability. Crafted from high-quality TA2 Titanium Alloy, this valve is designed for excellence. With a size of 2-1/2 inches (DN65) and a Class 150 LB (PN20) rating, it meets diverse industrial requirements. The valve features a Bolted Bonnet for secure closure, an Integral Seat for effective sealing, and RF ends for a dependable connection.

Request a quote

Tags

Detail Information

BS 1868 Titanium Swing Check Valve

Valve Description: Swing check valve, bolted bonnet, integral seat, stellite face, titanium

Body Material: Titanium Alloy TA2

Nominal Diameter: 2-1/2 Inch, DN65

Nominal Class: Class 150 LB, PN20

End Connection: RF

Metal Seat: STL

Design and Manufacture: BS 1868

Face to Face: ASME B16.10

Test and Inspection: API 598

The TA2 Titanium check valve is made of titanium material, including internal seals for the check valve. TA1, TA2, and TA10 Titanium check valves use corrosion-resistant and oxidation-resistant materials, making them very strong. These check valves can improve corrosion resistance and oxidation ability to adapt to the complex working conditions, ensuring longer-lasting operation. Titanium check valves work in humid atmospheres and sea water mediums, showing good performance, especially strong resistance to pitting corrosion, acid corrosion, and stress corrosion. TA1, TA2, and TA10 Titanium check valves exhibit excellent corrosion resistance to alkali, chloride, chlorine organic articles, nitric acid, etc.

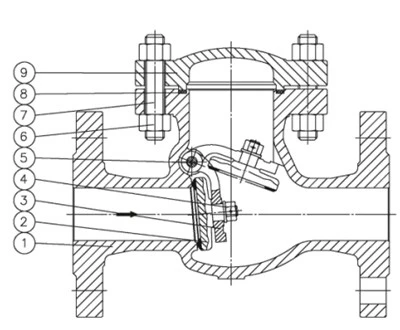

BS 1868 swing check valve prevents potentially damaging backflows to protect equipment like as pumps and compressors. The Non-return valves allow the flow of the fluid in one direction only and block reverse flows. It has the simplest design and operates via a metallic disc attached to a hinge at the top. When the fluid passes through the swing check valve, then the valve is open. When a reverse flow occurs, the changes in motion as well as gravity help to close the disc, closing the valve and preventing backflows.

BS 1868 Swing Check Valve - Standard

Welding seat rings or Renewable seat rings

Design and Manufacture: BS 1868 or ASME B16.34

Inspection and Test: API 598

End flange dimension: ASME B16.5, ASME B16.47 (API 605, MSS SP-44)

BW end dimension: ASME B16.25

Face to face, end to end: ASME B16.10

Pressure-temperature ratings: ASME B16.34

NACE: NACE 0175

Size Range: 2 Inch – 36 Inch

Pressure Range: ASME Class 150 - 2500 LB

Materials: ASTM A216 WCB, WCC, ASTM A217 WC1, WC6, WC9, ASTM A351 CF8, A351 CF8M, A351 CF3, A351 CF3M, A351 CN7M, ASTM A352 LC1, LCB, LCC, LC3, Hastelloy C276, Monel, Titanium and Alloy 20 (Cast Steel, Alloy Steel, Stainless Steel, Special Steel)

BS 1868 Swing Check Valve - Standard Material

| Parts Name | Carbon Steel to ASTM | Alloy Steel to ASTM | Stainless Steel to ASTM | ||||||||

| 1. | Body | A216 WCB | A352 LCB | A217 WC1 | A217 WC6 | A217 WC9 | A217 C5 | A351 CF8 | A351 CF8M | A351 CF3 | A351 CF3M |

| 9 | Cover | A216 WCB | A352 LCB | A217 WC1 | A217 WC6 | A217 WC9 | A217 C5 | A351 CF8 | A351 CF8M | A351 CF3 | A351 CF3M |

| 2. | Disc | A216 WCB | A352 LCB | A217 WC1 | A217 WC6 | A217 WC9 | A217 C5 | A351 CF8 | A351 CF8M | A351 CF3 | A351 CF3M |

| 3. | Hinge | A216 WCB | A352 LCB | A217 WC1 | A217 WC6 | A217 WC9 | A217 C5 | A351 CF8 | A351 CF8M | A351 CF3 | A351 CF3M |

| 7 | Bolt | A193 B7 | A320 L7 | A193 B7 | A193 B16 | A193 B16 | A193 B16 | A 193 B8 | A 193 B8 | A 193 B8 | A 193 B8 |

| 6. | Nut | A194 2H | A194 4 | A194 2H | A194 4 | A194 4 | A194 4 | A194 8 | A194 8 | A194 8 | A194 8 |

| 4. | Disc Nut | A194 2H | 410 | 410 | 410 | 410 | 410 | 304 | 316 | 304L | 316L |

| 8. | Gasket | SS Spiral Wound with graphite, or SS Spiral Wound PTFE, Reinforced PTFE | |||||||||

| 7. | Yoke | A216 WCB | A352 LCB | A217 WC1 | A217 WC6 | A217 WC9 | A217 C5 | A351 CF8 | A351 CF8M | A351 CF3 | A351 CF3M |

Comment Form