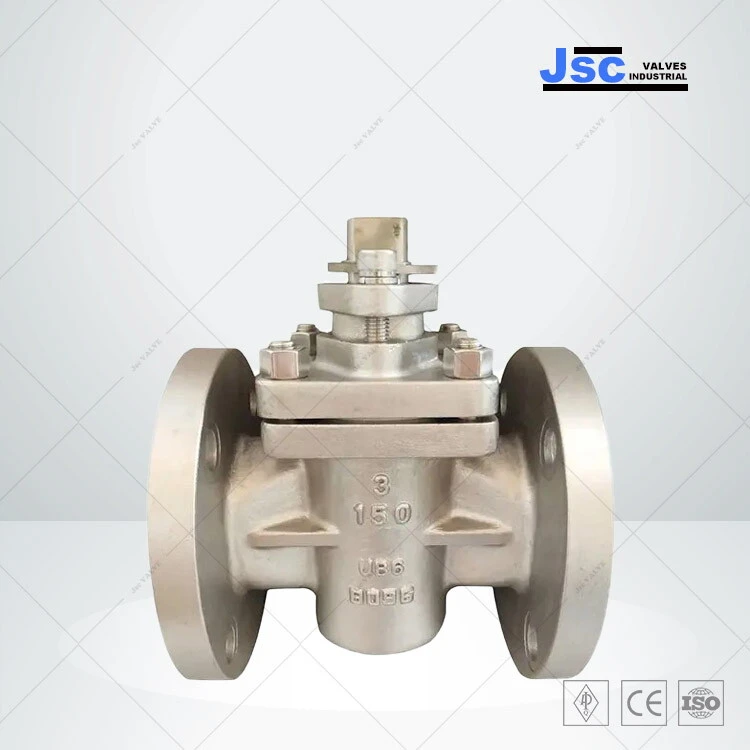

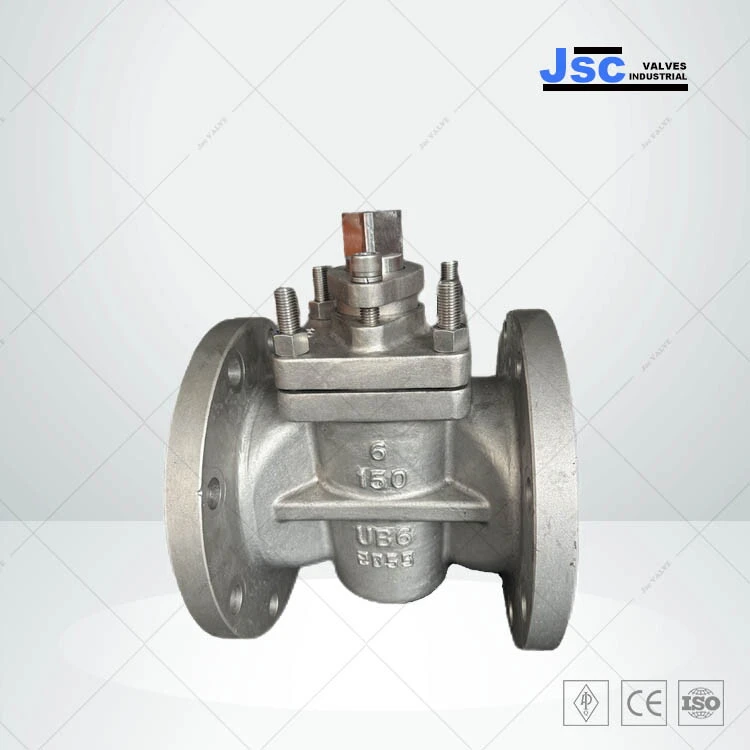

UB6 Plug Valve, DIN 1.4539, API 599, 6 IN, 150 LB, PTFE Seat

Key Specifications / Features

Model no.: JSC-240418-SPV-01

Hits: 10

Explore our advanced sleeved plug valve plant, meticulously crafted from super austenitic stainless steel UB6 or SS 904L, ensuring exceptional durability and corrosion resistance. Compliant with DIN 1.4539 and API 599 standards, this valve boasts a 6-inch (DN150) size, Class 150 LB (PN20) rating, and features a PTFE seat for reliable sealing performance. The inclusion of a lever mechanism allows for easy operation, while the RF (raised face) design ensures a secure and leak-free connection in your piping systems.

Request a quote

Tags

Detail Information

PTFE Sleeved Plug Valve

Valve description: Sleeved plug valve, PTFE seat

Body material: UB6 (DIN 1.4539, SS 904L)

Nominal diameter: 6 Inch (DN150)

Nominal pressure: Class 150 LB (PN20)

Design: API 599

Face to face: ASME B16.10

Mode of operation: lever

Test and inspection: API 598

Seat: PTFE

End connection: RF

The Super Austenitic UB6 or SS 904L Plug Valve, also known by material codes UNS N08904 and DIN 1.4539, is a high-alloy austenitic stainless steel plug valve. It boasts low carbon content and exceptional corrosion resistance, particularly in dilute sulfuric acid environments. Designed for harsh corrosion conditions, it features high chromium and sufficient nickel content. The addition of copper enhances its acid resistance, especially against chloride gap corrosion and stress corrosion cracking, minimizing corrosion spots and cracks. With slightly better pitting resistance than other steels, it offers good machinability and weldability, making it suitable for use in pressure vessels.

The PTFE-sleeved plug valve, according to ANSI standards, is suitable for cutting and connecting pipeline mediums in industries such as petroleum, chemical, pharmaceuticals, chemical fertilizers, and power generation. It operates under nominal pressures ranging from Class 150 to 900LB and temperatures from -29 to 180°C.

PTFE Sleeved Plug Valve-Feature

1. The product features a rational structure, dependable sealing, outstanding performance, and an appealing design.

2. Its sealing is achieved by the sleeve's surrounding sealing face, boasting a unique 360-degree metal edge for sleeve protection and fixation.

3. With no cavities for medium accumulation, the valve ensures cleanliness and is suitable for environments prone to stickiness.

4. Its dual-direction flow capability facilitates easy installation and use.

5. It offers a bi-directional, bubble-tight seal unaffected by line pressure and incorporates a static electricity eliminator in constant contact with the plug, ensuring safety in liquid media.

PTFE Sleeved Plug Valve-Specifications and Materials

Design & manufacture: API 599, ASME B16.34, DIN 3202

Pressure Rating: Class 150 LB – 600 LB, 1.0 MPa - 11.0 MPa, JIS 10K - 40K

Size Range: NPS 1/2 Inch - 24 Inch, DN15-DN600

Bore: Full bore, Reduced bore

Sleeve Material: PTFE, RPTFE, TFM, GF2P, PPL, PFA

Face to face dimensions: ASME B16.10

Flange ends: ASME B16.5

Butt-weld ends: ASME B16.25

Threaded Ends: ASME B1.20.1

Socket-weld Ends: ASME B16.11

Valves Marking: MSS SP-25

Inspection and testing: API 598

Valve description: Sleeved plug valve, PTFE seat

Body material: UB6 (DIN 1.4539, SS 904L)

Nominal diameter: 6 Inch (DN150)

Nominal pressure: Class 150 LB (PN20)

Design: API 599

Face to face: ASME B16.10

Mode of operation: lever

Test and inspection: API 598

Seat: PTFE

End connection: RF

The Super Austenitic UB6 or SS 904L Plug Valve, also known by material codes UNS N08904 and DIN 1.4539, is a high-alloy austenitic stainless steel plug valve. It boasts low carbon content and exceptional corrosion resistance, particularly in dilute sulfuric acid environments. Designed for harsh corrosion conditions, it features high chromium and sufficient nickel content. The addition of copper enhances its acid resistance, especially against chloride gap corrosion and stress corrosion cracking, minimizing corrosion spots and cracks. With slightly better pitting resistance than other steels, it offers good machinability and weldability, making it suitable for use in pressure vessels.

The PTFE-sleeved plug valve, according to ANSI standards, is suitable for cutting and connecting pipeline mediums in industries such as petroleum, chemical, pharmaceuticals, chemical fertilizers, and power generation. It operates under nominal pressures ranging from Class 150 to 900LB and temperatures from -29 to 180°C.

PTFE Sleeved Plug Valve-Feature

1. The product features a rational structure, dependable sealing, outstanding performance, and an appealing design.

2. Its sealing is achieved by the sleeve's surrounding sealing face, boasting a unique 360-degree metal edge for sleeve protection and fixation.

3. With no cavities for medium accumulation, the valve ensures cleanliness and is suitable for environments prone to stickiness.

4. Its dual-direction flow capability facilitates easy installation and use.

5. It offers a bi-directional, bubble-tight seal unaffected by line pressure and incorporates a static electricity eliminator in constant contact with the plug, ensuring safety in liquid media.

PTFE Sleeved Plug Valve-Specifications and Materials

Design & manufacture: API 599, ASME B16.34, DIN 3202

Pressure Rating: Class 150 LB – 600 LB, 1.0 MPa - 11.0 MPa, JIS 10K - 40K

Size Range: NPS 1/2 Inch - 24 Inch, DN15-DN600

Bore: Full bore, Reduced bore

Sleeve Material: PTFE, RPTFE, TFM, GF2P, PPL, PFA

Face to face dimensions: ASME B16.10

Flange ends: ASME B16.5

Butt-weld ends: ASME B16.25

Threaded Ends: ASME B1.20.1

Socket-weld Ends: ASME B16.11

Valves Marking: MSS SP-25

Inspection and testing: API 598

Comment Form